Facilities planners and designers should prepare plans that foster an appropriate flexibility and balance among initial investment and future expense to accommodate future change in owners’ interests, users’ needs, technology, and regulations. Postoccupancy evaluations (POE) can help in both delaying obsolescence and extending an existing building’s service life, when this after-the-fact assessment is used to make adaptations in the facility or its operations.

Few design elements highlight so clearly the design tradeoffs to be made between present and future costs. However, this approach conflicts with traditional facilities budgeting and procurement, which focus on first cost alone, preventing the effective consideration of these tradeoffs by dividing management responsibility. Consulting Group labs, built in 1975 near Princeton, New Jersey, also involved a low, glass-sheathed steel frame with exterior services and interior spaces unencumbered and easily modified.

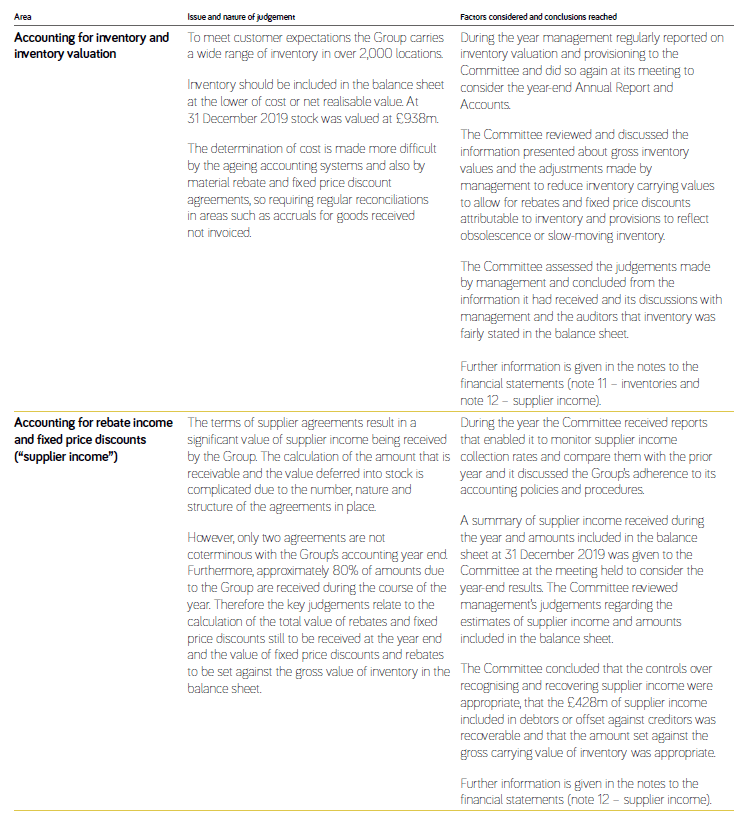

Inventory management recognizes several costs, one of them being obsolescence costs. Obsolescence costs are incurred when an item in inventory becomes obsolete before it is sold or used. Inventory may become obsolete due to product design changes, changes in customer demand, or by remaining unsold after an acceptable shelf life.

For example, installing clear polymer sheet over windows reduces energy loss, and using portable electric heaters can make work areas tolerable in facilities with obsolete or otherwise inadequate climate control systems. A variety of people must act to avoid or delay facilities obsolescence and its costs.

This testing also provides a basis for projecting the implications of new technology that could influence facility obsolescence. In the design of the 500,000-square-foot CIGNA Corporation headquarters building in the 1980s, for example, the design team used a 5,000-square-foot office mock-up to test lighting, office furniture, and a variety of design details for both user response and construction difficulty (Lemer, 1991). Such prototypes may help to extend the service life of the facility with respect to its first use.

Market Driven Obsolescence

In such cases some facilities permit the changes to be made relatively efficiently and economically, with less disruption to ongoing operations and lower costs to the building’s owner and occupants. As distinguished from adaptive reuse, the basic use remains unchanged, and the facility’s users hope to continue operations, with as little disruption as possible, during the course of the project. Sometimes it is difficult to foresee how people will respond to particular configurations of space and furnishings in a facility, under actual working conditions, and how their response will, in turn, influence facility subsystems performance. Equipment manufacturers and owners and designers of large facilities (or portfolios of similar facilities) can benefit by developing full-scale mock-ups of rooms to test user and subsystem response. Such prototypes allow testing of alternative work patterns and subsystem characteristics that reflect possible future demands on the finished facility.

What do you mean by obsolescence?

Obsolescence is a notable reduction in the utility of an inventory item or fixed asset. The determination of obsolescence typically results in a write-down of the inventory item or asset to reflect its reduced value.

The General Services Administration (GSA) real property inventory classifications could serve as a framework for characterizing facilities types (Federal Register, 1989a,b). According to VA estimates, from experience with more than 10 new VA hospitals built with the integrated building system and another 10 built in the private sector, VAHBS benefits are measured in remodeling costs that are only 70 percent of those for conventional designs. (In addition, faster construction and better performance have been achieved as well, purportedly with little or no increase in bid cost.) The Army has a somewhat similar system, developed under the acronym IBS (integrated building systems; also described in Appendix E).

Obsolete in Business Accounting

In many cases the owner or user’s fundamental response to functional obsolescence is changing a facility’s interior configuration. Faced with growth, downsizing, or reorganizations, or faced with the creation of new operations and the need for different spatial relationships among employees, these users or owners tear down some walls and put up others, and rearrange work stations and files. Sometimes a more comprehensive retrofit is undertaken, and changes include early replacement of electrical or communications systems, HVAC controls, life safety and security systems, lighting, elevators, and even exterior cladding.

- Driven by rapid technological changes, new components are developed and launched on the market with increasing speed.

- A growing industry sector is facing issues where life cycles of products no longer fit together with life cycles of required components.

- The result is a dramatic change in production methods of all components and their market availability.

Despite effective planning, design, and management, sometimes users or owners change and have requirements different from those that the facility was initially intended to fulfill. In addition, the technologies sometimes change, making facilities obsolete before they have worn out or otherwise failed. Owners pay many of the costs of obsolescence, and have the primary responsibility of managing their facilities in ways to avoid those costs. However, users of facilities—often not precisely the same people or organizations as the owners—often are burdened with costs of obsolescence as well.

Obsolescence

Georgetown University, for example, uses a “Facility Survey” to track the expected life of building systems as well as the schedule and estimated costs of anticipated replacement. Butt Grocery Company in San Antonio has established a POE process involving interviews, questionnaires, analysis of work records, and visits to employee work spaces to support reprogramming of the company’s headquarters facility at intervals of about 5 years (Stubbs, 1989). Allowing for expansion by constructing “extra” structure, foundation, and unfinished enclosed space increases initial cost but offers substantial reductions in life-cycle costs of obsolescence.

The problem of obsolescence is most prevalent for electronics technology, wherein the procurement lifetimes for microelectronic parts are often significantly shorter than the manufacturing and support life cycles for the products that use the parts. However, obsolescence extends beyond electronic components to other items, such as materials, textiles, and mechanical parts. In addition, obsolescence has been shown to appear for software, specifications, standards, processes, and soft resources, such as human skills. It is highly important to implement and operate an active management of obsolescence to mitigate and avoid extreme costs.

a structure whose service life has been exhausted and giving it a new function is one of the most dramatic responses to obsolescence. For example, the Army’s Construction Engineering Research Laboratory (CERL) has devised a database that could be such a means; the data base summarizes building repair costs by task, by component, and by system for Army projects. In so doing, the database can provide insights on the costs of obsolescence associated with certain building features. With additional input on the reasons for change, over—time and across a wide spectrum of structures—this information could help pinpoint key change agents and the areas where effective management approaches could be developed.

What are the types of obsolescence?

Definition of obsolescence. : the process of becoming obsolete or the condition of being nearly obsolete the gradual obsolescence of machinery reduced to obsolescence the planned obsolescence of automobiles.

Companies can use various accounting methods to calculate the depreciation of an asset on its books, but the overall goal is to measure and track an asset’s declining usefulness over time. This method of business planning also helps companies anticipate the need to sell or repurchase new assets. This book explores the meaning of obsolescence as the term applies to buildings.

Reduced setup times result in smaller lot sizes and less inventory, which reduces the risk of obsolescence. When obsolescence does occur in a facility subsystem, the user or owner typically pursues the strategy of “making do” for a period of time. Making do often involves finding low-cost ways to supplement performance that is no longer adequate, and there are a variety of products designed to support this approach to reducing the costs of obsolescence.

It discusses the functional, economic, technological, social, legal, political, and cultural factors that can influence when obsolescence will occur and considers what design professional and building owners and users can do to delay and minimize the costs of obsolescence. The analyses apply to all buildings, but public facilities are given added attention because of their special management problems. Public facilities are valuable assets that can provide decades of high quality of service if they are effectively utilized.

How Obsolete Assets Affect Your Business Taxes

These integrated systems have provided space that is very flexible and easy to maintain—valuable attributes for such facilities as hospitals and research laboratories. Programming and design professionals working with the owner then can prepare alternative program scenarios that reflect possibilities for the future. The most probable scenario is used as the primary basis for design, but the design can be tested for its ability to accommodate other scenarios, and modifications in the design might be made accordingly in to enhance the facility’s ability to accommodate alternate scenarios. Companies also take functional obsolescence into consideration in long-term business planning. Depreciation of an asset is one example of quantifiable functional obsolescence.

Driven by rapid technological changes, new components are developed and launched on the market with increasing speed. The result is a dramatic change in production methods of all components and their market availability. A growing industry sector is facing issues where life cycles of products no longer fit together with life cycles of required components. This issue is known as obsolescence, the status given to a part when it is no longer available from its original manufacturer.